Custom knives hold a special allure in the world of craftsmanship. They are not just tools; they are pieces of art, meticulously crafted to perfection. Among the myriad of custom knives, the custom dagger knife stands out with its sleek design and historical significance. In the world of Custom knives, I have my unique name for crafting dagger knives. In this journey from workshop to showcase, we delve into the intricate process of crafting a custom dagger knife, exploring its historical roots, modern applications, and the passion that drives artisans to create these masterpieces.

Custom knives have always held a certain mystique, captivating collectors and enthusiasts alike. They represent a fusion of functionality and beauty, each telling a unique story of craftsmanship and creativity. At the heart of this fascination lies the custom dagger knife, a symbol of elegance and precision. In this article, we embark on a journey to discover the process behind crafting a custom dagger knife, from its humble beginnings in the workshop to its grand showcase on display.

Understanding the Dagger Knife

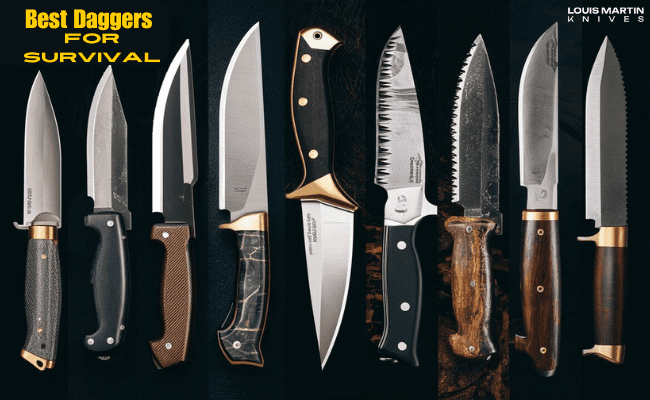

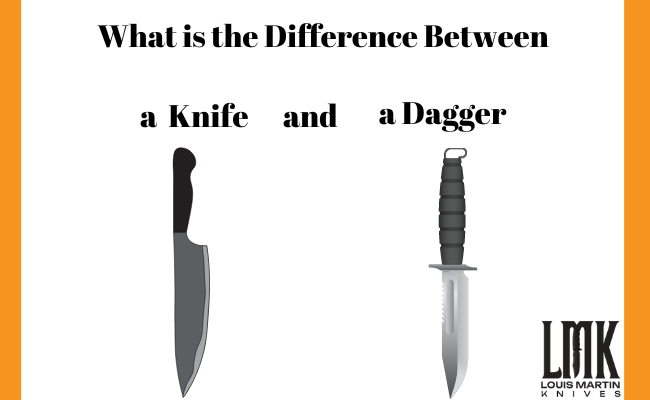

To truly appreciate the artistry behind the custom Dagger knife it is essential to understand its historical significance and cultural relevance. Dating back centuries, the dagger has played a prominent role in various civilizations, serving as both a weapon and a symbol of status. Characterized by its double-edged blade and sharp point, the dagger embodies the essence of precision and lethality. In modern times, the dagger knife has found new applications in survival, self-defense, and even as a collector’s item, showcasing its enduring appeal in the ever-evolving landscape of custom knives.

Conceptualization Phase

Every custom Push dagger knife begins with a spark of inspiration. Whether drawing from historical designs or exploring innovative concepts, the journey from idea to execution is filled with creativity and vision. Research and design considerations play a crucial role in shaping the final product, with artisans meticulously studying materials, ergonomics, and aesthetic elements. Initial sketches and brainstorming sessions serve as the foundation upon which the top custom dagger knife takes shape, laying the groundwork for the crafting process ahead.

Crafting Process

Crafting a Custom Handmade dagger knife is a labor of love, requiring skill, patience, and attention to detail. The selection of materials is of paramount importance, with artisans opting for high-quality steel and exotic handle materials to ensure durability and visual appeal. In the workshop, a symphony of tools comes to life, each playing a vital role in the forging process. From shaping the blade to heat treatment and tempering, every step is executed with precision and care.

Crafting the handle is an art in itself, with artisans sculpting wood, bone, or metal to create a seamless blend of form and function. Finally, fine-tuning and polishing give the top custom dagger knife its signature shine, ready to stand as a testament to the artisan’s craftsmanship.

Challenges and Triumphs

Like any creative endeavor, crafting a custom dagger knife is not without its challenges. From technical hurdles to unforeseen setbacks, artisans must navigate a maze of obstacles on the path to completion. Yet, amidst the trials and tribulations, there are moments of triumph moments of creativity, and innovation that push the boundaries of what is possible. Each challenge is met with determination and resolve, ultimately leading to a greater understanding of the craft and the satisfaction of overcoming adversity.

Bringing the Knife to Life

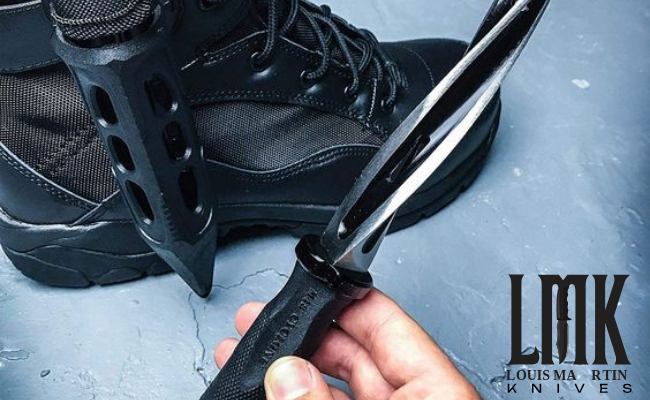

As the final touches are applied and the last inspections are made, the custom dagger knife begins to take on a life of its own. Quality assurance and testing ensure that every aspect meets the highest standards of excellence, guaranteeing a product that is as functional as it is beautiful. Everyday carry Personalization options offer clients the opportunity to make the best custom dagger knife truly their own, with custom engravings, embellishments, and handle materials adding a personal touch to the finished product.

Testing and Quality Assurance

The meticulous process of crafting a custom dagger knife, rigorous testing, and quality assurance play pivotal roles. Assessing blade sharpness and edge retention ensures the knife’s effectiveness in various cutting tasks, guaranteeing precision and efficiency. Equally important is evaluating handle comfort and grip, as these factors directly impact the wielder’s control and maneuverability.

Beyond ergonomics, a thorough examination of overall durability and functionality ensures the knife’s reliability and longevity in diverse scenarios. Through stringent quality checks, from blade to handle, craftsmen uphold their commitment to delivering not just a tool, but a finely crafted masterpiece worthy of showcase and admiration.

Showcasing the Finished Product of the Dagger knife

Handmade Louis Martin Fixed Blade Damascus Wootz Ice Pick Dagger Knife

SPECIFICATIONS

overall length: 10.0”

HandleLength: 5.0”

BladeLength: 5.0”

Width: N/A

CuttingEdge: N/A, Sharpened at 20 Degrees

HandleMaterial: Wootz

GuardType: N/A

BladeType: Ice Pick Dagger Knife

Tempered: Oil Tempered to 58-60HRC

DESCRIPTION

An ice pick is a tool that is used to crack, pick, or chip ice. It has the shape of a scratch awl for wood. Ice picks were a common home item used to separate and shape the chunks of ice used in iceboxes before contemporary freezers.

This fine handmade knife would look impressive in any knife collection or be a workhorse as a daily carry item.

Conclusion

The journey from workshop to showcase is a testament to the artistry and dedication involved in crafting a custom dagger knife. From its historical roots to its modern applications, the dagger knife continues to captivate and inspire, serving as a timeless symbol of craftsmanship and ingenuity. As we reflect on the intricate process behind its creation, we gain a newfound appreciation for the artisans who bring these masterpieces to life. So, to all who dare to embark on their best custom knife-making adventures, may your blades be sharp, your hands steady, and your creativity boundless.

FAQs

What makes custom dagger knives unique?

Custom dagger knives are unique due to their intricate designs, high-quality materials, and the skilled craftsmanship involved in their creation. Each knife is meticulously crafted to perfection, making it a one-of-a-kind piece of art.

What are the primary materials used in crafting custom dagger knives?

Custom dagger knives are typically made from high-quality steel for the blade, and the handles may be crafted from materials such as wood, bone, or metal. Artisans often choose exotic materials to enhance the knife’s durability and visual appeal.

How can I personalize my custom dagger knife?

Many artisans offer personalization options such as custom engravings, embellishments, and handle materials. This allows clients to make their custom dagger knife truly their own, adding a personal touch to the finished product.

Where can I find custom dagger knives for purchase?

Custom dagger knives can be purchased directly from artisans through their online platforms, or they may be available at knife shows and exhibitions. Researching reputable craftsmen and exploring their portfolios is a good starting point for finding the perfect custom dagger knife.