Custom knives are a testament to craftsmanship and individuality, with each piece representing a unique blend of artistry and functionality. One crucial aspect of crafting a custom knife is selecting the right handle material. In this comprehensive guide, we’ll explore various materials used in crafting custom knife handles, considering their properties, applications, and the intricacies involved in working with them.

Definition of Custom Knife Handles

Custom knife handles refer to the personalized grips attached to the blade, enhancing both aesthetics and functionality. Craftsmen often create these handles with precision, taking into account the user’s preferences, the knife’s purpose, and the desired visual appeal.

Selecting Appropriate Custom Knife Handles Materials

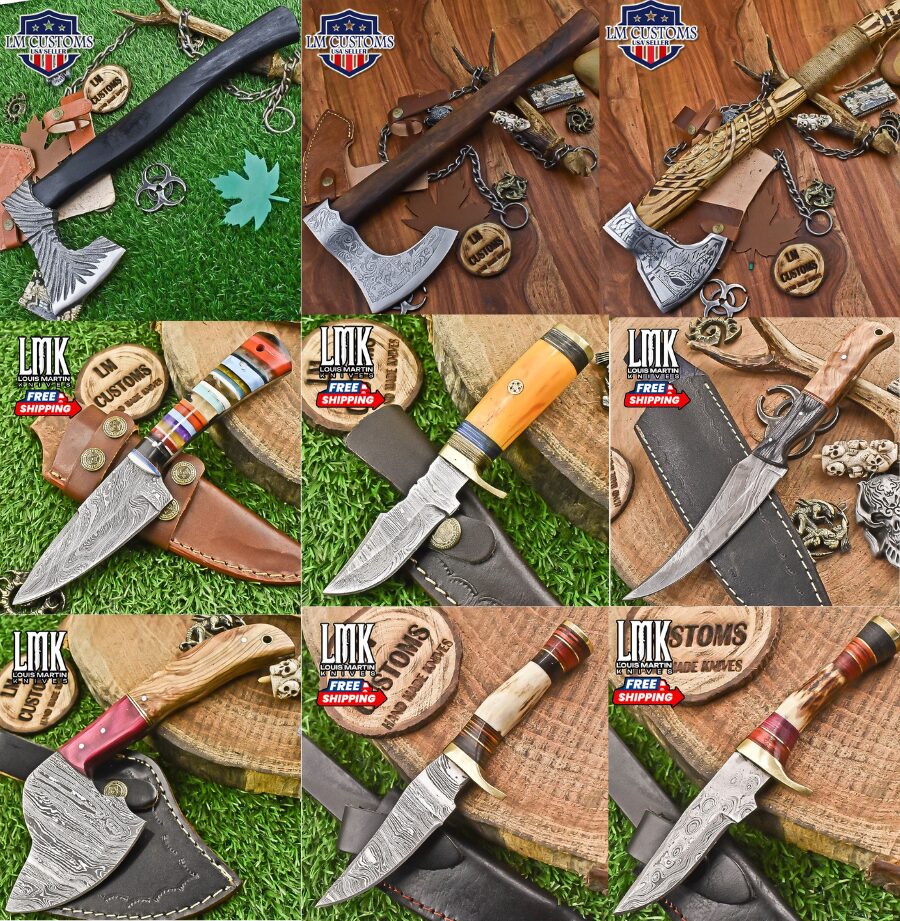

Choosing the right handle material is paramount as it directly influences the knife’s performance, durability, and overall feel. Whether crafting hunting knives, pocket knives, dagger knives, karambit knives, kukri knives, skinning knives, chef knives, or bowie knives, understanding the characteristics of different materials is essential for creating a bespoke and high-quality product.

Overview of Common Custom Knife Handle Materials

Natural Materials

Wood

Wooden handles are a classic choice for custom knives, offering a timeless aesthetic and a comfortable grip. Common types of wood include walnut, rosewood, and ebony. Each wood type has distinct characteristics, ranging from grain patterns to hardness, allowing for a wide range of design possibilities.

Characteristics and Properties

Wooden handles provide a warm and natural feel, making them suitable for various knife types. They can be carved, shaped, and finished to meet the specific requirements of the knife maker and user.

Pros and Cons – Custom knife Handles

Pros: Aesthetic versatility, comfortable grip, and a traditional appeal.

Cons: Susceptible to moisture and temperature changes, requiring proper maintenance.

Horn and Bone

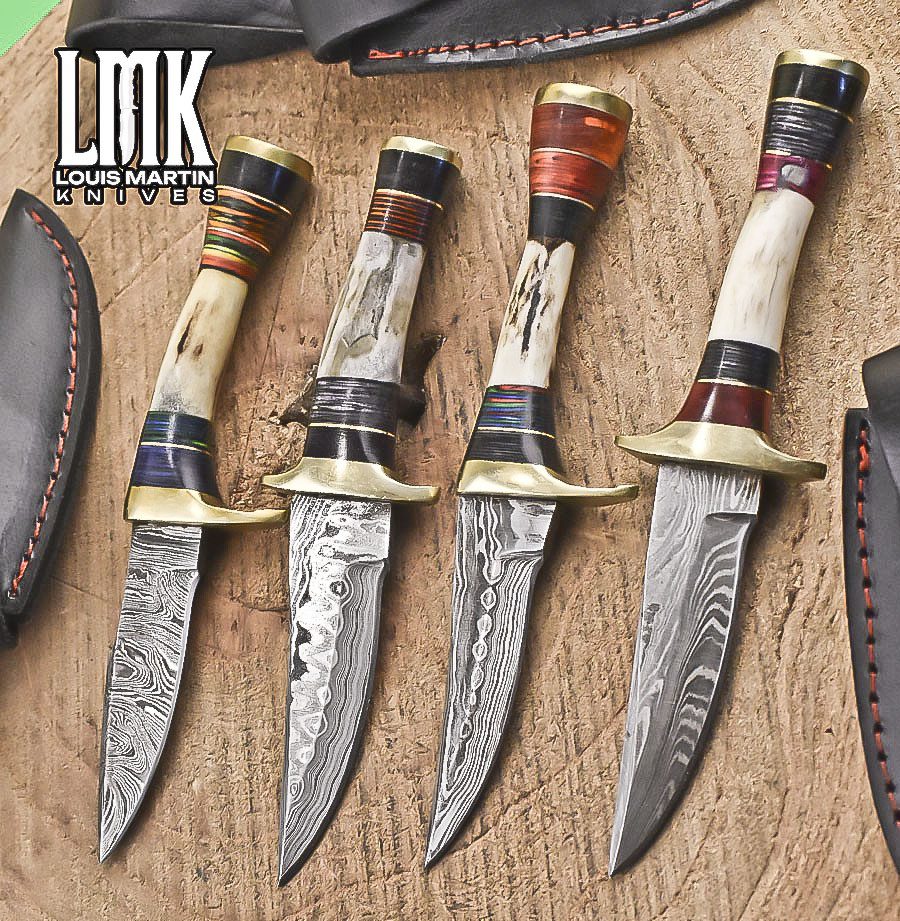

Buffalo Horn, Stag Horn, and Other Options

Horn and bone handles add a rustic charm to custom knives. Buffalo horn and stag horn, in particular, are popular choices due to their durability and unique textures. The variations in color and pattern make each handle distinct.

Considerations for Each Type

Buffalo horn offers a smooth and polished finish, while stag horn provides a more textured and rugged appearance. The choice depends on the desired aesthetic and the custom knife intended use.

Aesthetic Appeal and Durability

Handles made from horn and bone boast natural variations, ensuring that each knife is truly one-of-a-kind. While durable, these materials require proper care to prevent deterioration.

Synthetic Materials

G10

Composition and Construction

Custom knife G10, a fiberglass laminate, is a synthetic material known for its strength and resilience. It is created by layering fiberglass fabric with epoxy resin, resulting in a lightweight yet durable material.

Strengths and Weaknesses

G10 handles offer excellent strength-to-weight ratio, making them suitable for a wide range of knives. However, they may lack the warmth and organic feel of natural materials.

Popular Applications

G10 handles are widely used in tactical and outdoor knives due to their resistance to moisture and chemicals. They are also favored for their textured surface, providing a secure grip.

Micarta

Fabric-Based Composite

Micarta custom knife is a composite material made from layers of fabric soaked in resin. These layers are compressed and cured to create a durable and stable material.

Variations in Colors and Textures

Micarta handles come in various colors and textures, offering versatility for customization. The material provides a solid grip and is resistant to wear, making it suitable for heavy-duty knives.

Resistance to Wear and Weather

Micarta custom knife handles are known for their resistance to wear, weather, and chemicals, making them an ideal choice for knives intended for outdoor and rugged use.

High-Tech Materials

Carbon Fiber

Lightweight and Durable

Carbon fiber is a high-tech material known for its exceptional strength-to-weight ratio. It is created by weaving carbon strands together and bonding them with resin, resulting in a lightweight and robust handle material.

Modern Aesthetic Appeal

Carbon fiber handles exude a modern and sleek aesthetic, making them popular in contemporary custom knife designs. The material’s unique patterns and textures add visual appeal to the finished product.

Challenges in Working with Carbon Fiber

While carbon fiber is praised for its strength, it can be challenging to work with due to its hardness. Craftsmen need specialized tools and techniques to shape and finish carbon fiber handles accurately.

Titanium

Lightweight and Corrosion-Resistant

Titanium is a lightweight metal known for its corrosion resistance and strength. Titanium custom knife handles are popular for their durability and ability to withstand harsh environmental conditions.

Customization Options

Titanium handles can be anodized to achieve various colors, allowing for personalization and customization. This feature makes them popular among knife enthusiasts seeking a unique look.

Considerations for Practical Use

Titanium handles are suitable for various custom knife types, providing a balance of strength and weight. However, they may not offer the same warmth as natural materials.

Exotic Materials

Louis Martin Knives specializes in crafting custom knife handles using exotic materials, pushing the boundaries of creativity and craftsmanship.

Mother of Pearl

Unique Aesthetic Qualities

Mother of Pearl handles exhibit a luxurious and iridescent appearance, making them a sought-after choice for high-end custom knives. The natural luster and colors add a touch of elegance to any blade.

Challenges in Working with Mother of Pearl

Crafting custom knife handles from Mother of Pearl requires precision and skill due to the material’s brittle nature. Specialized techniques are employed to create durable and visually stunning handles.

Damascus Steel

Artistic and Functional Aspects

Damascus steel, known for its unique patterns created through layering different metal alloys, is often incorporated into custom knife handles. This not only adds an artistic touch but also enhances the handle’s strength and durability.

How Damascus Steel is Incorporated into Handles

Craftsmen carefully forge and shape Damascus steel to create intricate patterns, which are then integrated into the handle design. This process requires expertise to ensure a seamless and visually appealing result.

Choosing the Right Material

Louis Martin Knives focuses on providing custom knife handles that meet the specific needs and preferences of their clients. When selecting a handle material, several factors must be considered.

Factors to Consider When Selecting Handle Materials

Intended Use of the Knife

Consider the purpose of the custom knife—whether it’s a hunting knife, pocket knife, dagger knife, karambit knife, kukri knife, skinning knife, chef knife, or bowie knife. Each type of knife demands specific characteristics in a handle, such as durability, grip, and comfort.

Ergonomics and Comfort

The ergonomics of a knife handle play a crucial role in user comfort and control. Louis Martin Knives takes pride in creating handles that not only look exquisite but also feel comfortable in the user’s hand.

Aesthetic Preferences

Personal style and aesthetic preferences are vital considerations when choosing a custom knife handle. Louis Martin Knives offers a diverse range of materials and designs, allowing clients to express their individuality.

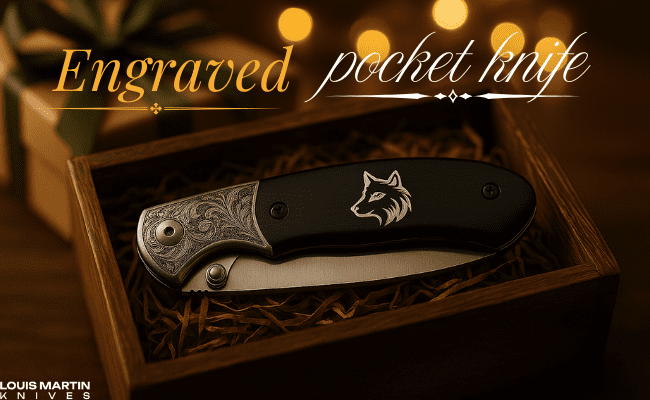

Personalization and Customization

Louis Martin Knives embraces the art of personalization, allowing clients to customize their knife handles according to their unique tastes. From selecting materials to choosing specific design elements, every aspect of the handle can be tailored to the client’s vision.

Customizing Handles to Individual Preferences

Clients can choose from a variety of custom knife materials, including natural options like wood, horn, and bone, or opt for high-tech materials such as carbon fiber and titanium. The selection process involves considering the desired aesthetic, functionality, and personal connection to the material.

Popular Trends in Custom Handle Designs

Louis Martin Knives stays abreast of the latest trends in custom handle designs. From minimalist and modern to intricate and traditional, the craftsmen at Louis Martin Knives are adept at bringing diverse design concepts to life.

Care and Maintenance

Proper care and maintenance are essential to ensuring the longevity and performance of custom knife handles. Different materials require specific attention.

General Care Tips for Various Materials

- Wooden handles should be regularly oiled to prevent drying and cracking.

- Horn and bone custom knife handles benefit from periodic conditioning to maintain their luster.

- Synthetic materials like G10 and Micarta are easy to clean and resistant to moisture, but regular wiping is recommended.

Restoration and Refinishing Options

Louis Martin Knives offers restoration and refinishing services to breathe new life into old or worn handles. Whether it’s re-polishing a horn handle or refinishing a carbon fiber grip, the craftsmen ensure that the handle looks as good as new.

Addressing Common Issues with Specific Materials

Understanding the peculiarities of each material allows Louis Martin Knives to address common issues effectively. From repairing small cracks in wooden handles to refining scratches on titanium, the craftsmen possess the expertise to handle a variety of challenges.

Conclusion

Custom knife handles like, bowie knives and kukri knives or more knives are rich with diverse materials, each offering a unique set of characteristics and challenges. This guide has explored natural materials like wood, horn, and bone, synthetic materials such as G10 and Micarta, and high-tech materials like carbon fiber and titanium. Additionally, we delved into the exotic materials used by Louis Martin Knives, including Mother of Pearl and Damascus steel.

Exploration and Creativity in Custom Knife Handles Making

The process of choosing the right material involves careful consideration of factors like intended use, ergonomics, and aesthetic preferences. Louis Martin Knives stands out as a beacon of craftsmanship, offering personalized and customizable handles that cater to individual tastes.

As you embark on your journey into the world of custom knives, let this guide serve as a compass, guiding you through the vast array of materials and inspiring creativity in your own knife-making endeavors.

Answers for the Questions

Which is better: G10 or Micarta?

The choice between G10 and Micarta ultimately depends on personal preferences and the intended use of the knife. G10 is a fiberglass laminate known for its strength, durability, and resistance to moisture and chemicals. It has a textured surface, providing a secure grip, making it popular for tactical and outdoor knives.

On the other hand, Micarta, a fabric-based composite, is also durable and resistant to wear and weather. It offers a solid grip and comes in various colors and textures, allowing for customization. The decision between G10 and Micarta should consider factors such as aesthetic preferences, intended application, and the feel of the material in hand.

Can you rehandle a knife?

Yes, knives can be rehandled, and the process is known as “rehandling.” Rehandling involves replacing the existing handle with a new one, often to improve aesthetics, comfort, or functionality. This process requires skill, as the new handle must be securely attached to the blade without compromising the knife’s balance.

The choice of custom knife materials for the new handle can vary based on personal preference and the desired characteristics of the knife. Professional knife makers or experienced craftsmen typically perform rehandling to ensure a precise and secure fit.

What is the most comfortable knife handle shape?

The most comfortable custom knife handle shape is subjective and varies depending on individual preferences and the intended use of the knife. However, many people find handles with ergonomic designs to be the most comfortable. Handles that fit naturally into the hand, providing a secure grip and minimizing hand fatigue during extended use, are often preferred.

Common ergonomic handle shapes include those with finger grooves, contoured grips, and designs that conform to the natural curves of the hand. Ultimately, the most comfortable knife handle shape is one that feels secure and natural in the user’s hand.

What’s a knife handle called?

The handle of a knife is commonly referred to simply as the “handle.” It is the part of the knife that is gripped by the user and is attached to the blade. The handle serves to provide a comfortable and secure grip, allowing the user to control the custom knife during various cutting tasks.

While there may be specific terms or names for handles in certain contexts or designs (such as scales for folding knives), in general, it is commonly known as the knife handle.