In the bustling world of industry and manufacturing, efficiency is key. Every operation, whether it’s in a factory or a warehouse, thrives on its ability to optimize processes and reduce downtime. One tool that has made significant strides in boosting efficiency while prioritizing safety is the Damascus knife. In this blog post, we will delve into the fascinating evolution of Damascus knives, exploring how they’ve become sharper, safer, and smarter over the years, and how these advancements have contributed to increased efficiency in various work environments.

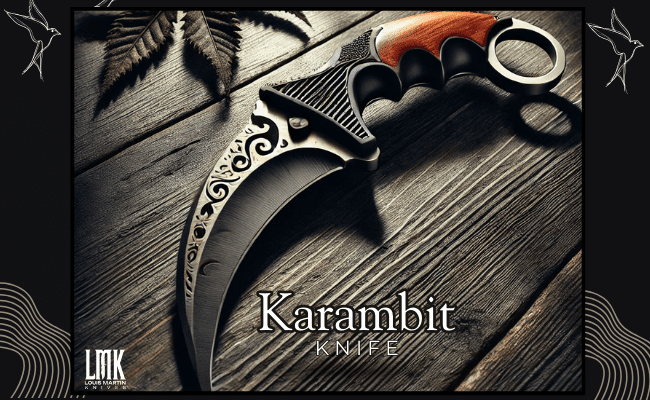

The Early Days of Damascus Knives

Damascus knives have come a long way since their inception. In their early days, they were primarily designed for one purpose: to prevent workplace accidents. These knives featured retractable blades, ensuring that the blade was only exposed when necessary. While safety was paramount, efficiency often took a back seat.

The Sharp Evolution

As technology advanced, safety knives evolved to become sharper and more versatile. Blade materials improved, with high-quality stainless steel and carbon blades replacing their predecessors. This upgrade made cutting through a range of materials, from cardboard to plastic, more efficient Moreover, the blades themselves became replaceable, allowing workers to maintain a consistently sharp cutting edge. This development significantly reduced the time spent changing knives or dealing with dull blades, thereby increasing productivity.

Safety First, Always

One of the most critical aspects of Damascus knives is their commitment to minimizing workplace injuries. Louis Martin safety knives are designed with user safety in mind. They incorporate features such as blade guards and ergonomic handles, which ensure that users can handle the knives without compromising their well-being. Additionally, some safety knives now include automatic blade retraction mechanisms. These mechanisms are engineered to retract the blade the moment it loses contact with the material being cut. This virtually eliminates the risk of accidental cuts, making the workplace safer than ever.

The Smart Revolution

In today’s age of smart technology, LM knives have joined the fray. Some models are now equipped with built-in sensors and indicators. These knives can monitor blade wear and alert users when it’s time to replace the blade, preventing the use of a dull blade that could reduce efficiency and compromise safety. Furthermore, some safety knives are now integrated with RFID technology. This enables businesses to track tool usage, ensuring that knives are not misplaced or misused, ultimately contributing to cost-efficiency.

A Diverse Range of Applications

The evolution of safety knives isn’t limited to just one industry or use case. These versatile tools have found their place in various sectors, from manufacturing and warehousing to agriculture and construction. In the food industry, for instance, knives are used to efficiently open packaging without contaminating the contents. In warehousing, they help streamline operations by making it easier to cut through layers of packaging materials. In construction, they ensure precise cutting while minimizing the risk of injuries on-site.

Efficiency and Cost Savings

Perhaps one of the most significant impacts of the evolution of Louis Martin knives is their contribution to efficiency and cost savings. The combination of sharp blades, ergonomic designs, and safety features has led to a significant reduction in workplace accidents. This translates to lower workers’ compensation claims and less downtime due to injuries, ultimately resulting in substantial cost savings for businesses. Efficiency gains are also notable in terms of time saved during cutting operations. The improved blade quality and ease of use allow workers to complete tasks more quickly, increasing overall productivity.

The Future of Louis Martin Knives

As technology continues to advance, LM knives will likely undergo further innovations. Future iterations may incorporate even smarter features, such as real-time monitoring of blade sharpness and usage patterns. These knives could become an integral part of the Internet of Things (IoT), contributing to data-driven decision-making in various industries.

In conclusion, LM knives have come a long way from their humble beginnings as tools solely focused on injury prevention. They have evolved to become sharper, safer, and smarter, making them invaluable assets in a wide range of industries. With their continued evolution, LM knives will likely play a pivotal role in enhancing efficiency and safety in workplaces worldwide. As they become more integrated with smart technology, the future looks bright for these indispensable tools.

The journey of LM knives reflects the broader narrative of innovation in the workplace. As technology and safety standards continue to advance, the tools we use daily are becoming not just safer but also more efficient. The evolution of Louis Martin Damascus knives stands as a testament to human ingenuity, where the goal is not just to get the job done but to get it done safely and efficiently.