Top Knives are special in various fields, from culinary arts to industrial applications. Their precision and quality can make all the difference in performance. But how are these best knives crafted? Enter LMK technology, short for Likely Material Knives, a cutting-edge approach revolutionizing the way top knives are made. In this exploration, we’ll delve into the depths of traditional methods and juxtapose them with innovative LMK technology. With Custom Knives, Our journey will uncover the intricacies of 3D printing, CNC machining, and the timeless art of handcrafting, all through the lens of LMK.

Let’s embark on this odyssey to unravel the secrets behind the creation of top knives.

Traditional Methods of Making Top Knives

Before the advent of LMK technology, artisans relied on traditional knife-making techniques. These methods, passed down through generations, hold a sense of craftsmanship and heritage.

From forging to grinding, each step in the process contributes to the creation of a masterpiece. However, traditional methods have their pros and cons. While they offer a sense of authenticity and customization, they can be labor-intensive and time-consuming. Examples of traditional knife-making processes include forging, stock removal, and hand grinding.

Introduction to LMK Technology

LMK technology introduces a paradigm shift in the world of knife-making. Unlike traditional methods, LMK leverages modern advancements to streamline the production process. Through innovative materials and techniques, LMK offers Top Wholesale Knives Its key advantages include enhanced durability, flexibility in design, and rapid prototyping capabilities. LMK technology stands apart by embracing digital fabrication and cutting-edge materials, setting a new standard for top knife production.

Different Ways of Making Top Knives with LMK

3-D Printing Top Knives with LMK: 3-D printing with LMK opens doorways to countless opportunities. By layering substances precisely, difficult designs can be found simply. The advantages of 3D printing for top knives include rapid prototyping, complex geometries, and decreased material waste. However, demanding situations including surface end and material limitations should be addressed.

CNC Machining Top Knives with LMK: CNC machining offers extraordinary precision and consistency in top knife production. By making use of computer-managed tools, complex designs can be replicated with utmost accuracy. The blessings of CNC machining consist of excessive repeatability, tight tolerances, and scalability. Considerations for precision and customization are paramount when employing CNC machining with LMK.

Handcrafting Top Knives with LMK: While technology has its region, the artisanal approach to knife-making remains timeless. Handcrafting pinnacle knives with LMK allows for personal contact and interest in detail. The benefits of handcrafting consist of particular designs, bespoke creations, and an experience of artistry. However, challenges together with exertion intensiveness and ability requirements must be recounted.

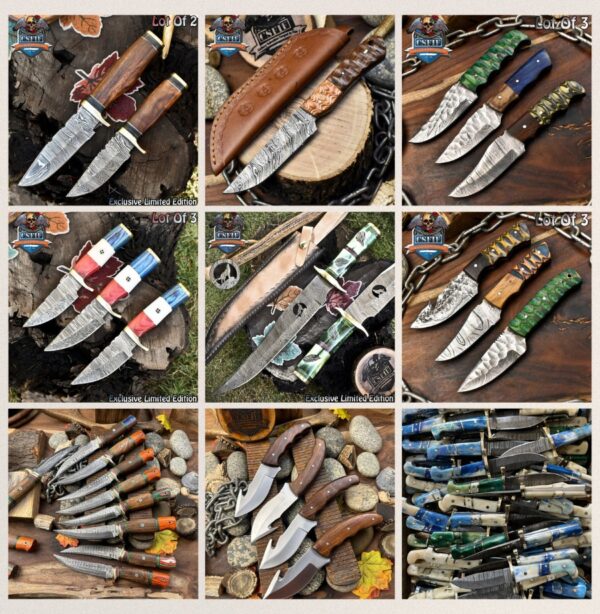

List of LMK Top Knives

Damascus Knives: Crafted using LMK technology, Damascus knives are renowned for their exquisite patterns and exceptional sharpness. LMK allows for precise fabrication of the intricate Damascus steel, resulting in stunning blades that are both functional and visually striking.

Hunting Knife: LMK technology revolutionizes the production of hunting knives, offering durability, reliability, and precision. Whether for field dressing, skinning, or general outdoor tasks, LMK hunting knives are engineered to withstand rugged conditions and deliver optimal performance.

Chef Knife: Chef knives made with LMK technology represent the pinnacle of culinary craftsmanship. With razor-sharp edges and ergonomic designs, these knives offer chefs unparalleled control and efficiency in the kitchen. LMK ensures precision in blade geometry and balance, allowing chefs to achieve perfect cuts with ease.

Bowie Knife: LMK Bowie knives pay homage to the classic design while incorporating modern engineering principles. With sturdy construction, ergonomic handles, and razor-sharp blades, these knives are ready to tackle any challenge, whether in the wilderness or on display in a collector’s cabinet.

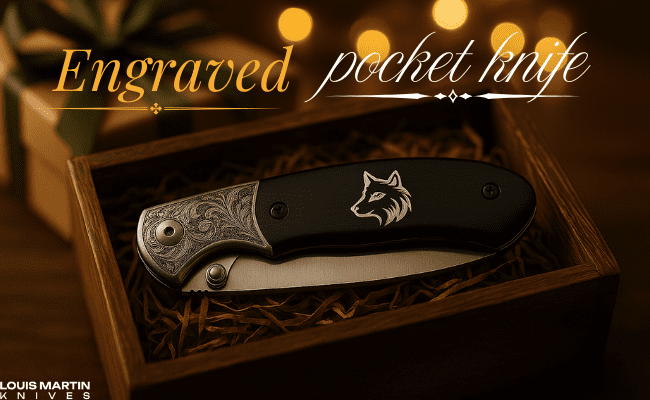

Pocket Knife: Pocket knives crafted with LMK technology combine compact design with uncompromising functionality. Featuring precision-engineered blades and durable materials, LMK pocket knives offer reliability and convenience for everyday tasks, from cutting boxes to outdoor adventures.

Folding Knife: LMK folding knives exemplify the marriage of innovation and tradition. With precision-machined mechanisms and high-quality materials, these knives offer smooth deployment and robust performance. Whether for everyday

Comparative Analysis

Comparing traditional techniques with the LMK era sheds light on their respective strengths and weaknesses. While traditional techniques provide a feel of background and craftsmanship, the LMK generation excels in precision and performance. Evaluating elements consisting of exceptional, performance, and price-effectiveness gives insights into deciding on the finest technique for top knife manufacturing. Additionally, concerns of environmental impact and sustainability play a critical function in choice-making.

Custom Knives Like No Others

LMK Custom Knives represent the epitome of craftsmanship and innovation in the world of blade crafting. Melding the precision of modern technology with the artistry of traditional handcrafting, LMK Custom Knives offer discerning enthusiasts and professionals alike a bespoke experience like no other. Each knife is meticulously crafted to exact specifications, ensuring unparalleled quality and performance.

Future Perspectives and Conclusion

As we gaze into the horizon, the future of LMK technology in Top knife manufacturing seems promising. Potential improvements, along with superior materials and automation, promise to similarly beautify fine and efficiency. Emerging traits, along with customized layouts and sustainable practices, are poised to shape the landscape of knife-making. In conclusion, the versatility and capability of LMK generation in the knife-making industry are simple.

Frequently Asked Questions

What are the conventional techniques for making top knives?

Traditional techniques of making top knives encompass forging, stock removal, and hand grinding. These techniques, handed down through generations, involve manual craftsmanship and meticulous interest in each element.

How does LMK technology range from traditional strategies?

LMK era differs from traditional techniques by way of leveraging modern-day advancements in materials and fabrication techniques. It carries virtual fabrication, 3-D printing, CNC machining, and revolutionary substances to streamline the manufacturing technique and enhance precision.

What are the blessings of using LMK for knife-making?

Some advantages of using LMK for knife-making consist of stronger sturdiness, flexibility in layout, speedy prototyping competencies, and particular customization. LMK technology allows the introduction of intricate designs with unprecedented precision and performance.